We work to identify, from the product design phase, solutions applicable to all our collections. Some collections are innovation laboratories, such as those experimented with the Re-up upcycling project and with OVS Cotone Italiano.

MATERIALS

The choice of materials is fundamental in the design of a garment, as it determines approximately 60% of the impacts of the finished garment. Our assortment will gradually be created only with materials that minimize impact (or regenerative) and are fully compatible with circularity systems (biological or technological).

Where possible fibers of natural origin are preferred, in particular cotton which represents 65% of the materials used on the total assortment (compared to a much lower global use).

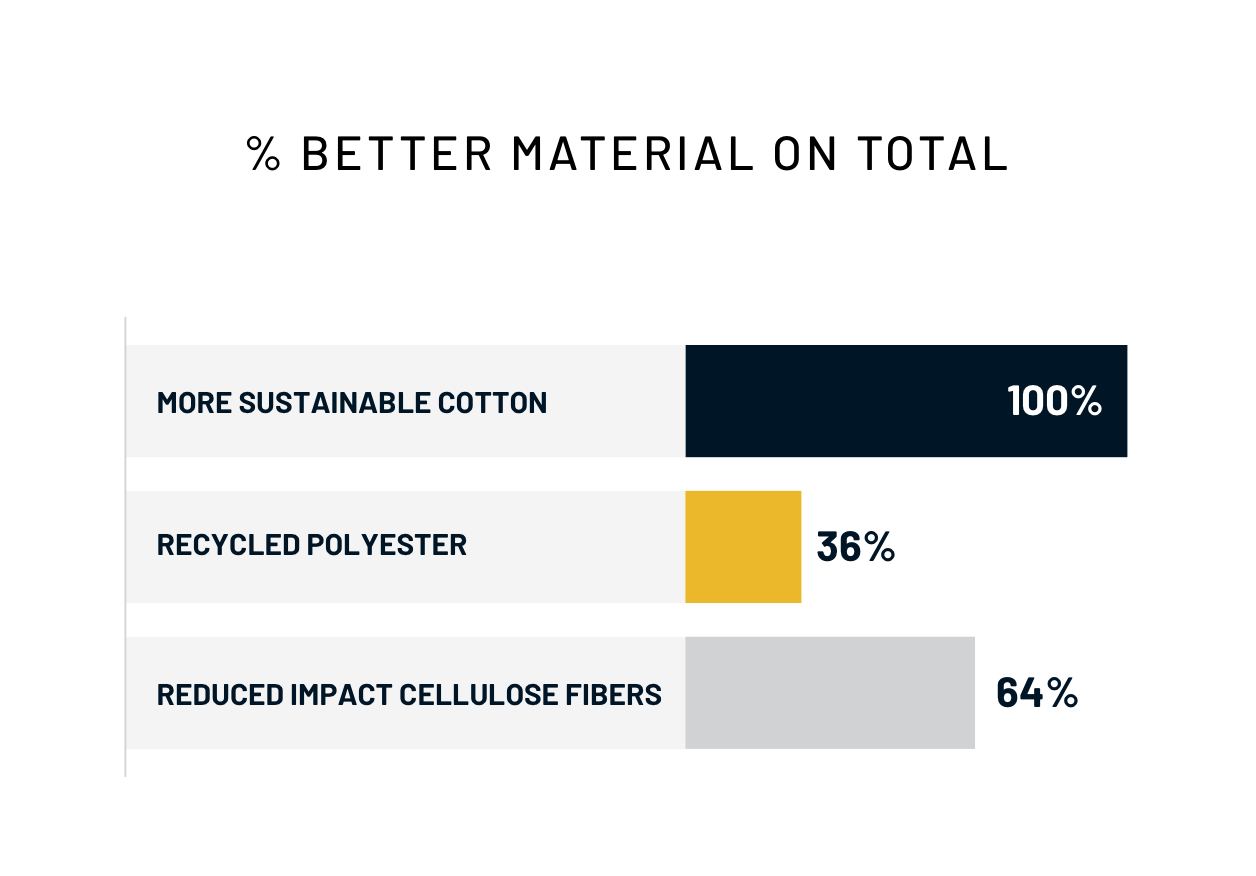

The main interventions on the material sourcing strategy concern the most used fibers in our collections: cotton, polyester and materials of cellulose origin with the target, by 2026, of having 65% of “Better material”, materials coming from the chain of custody with reduced impact.

-

Cotton

100% of OVS cotton is either recycled, organic, Cotton Made in Africa or cultivated according to Better Cotton Standard.

We purchase more than 25 thousand tons of cotton every year, which represents 65% of the materials used in our products.

However, we are aware of the fact that using natural fiber does not always mean having a low impact on the environment.

Conventional cotton cultivation involves less than 3% of cultivated land, but it is responsible for the use of 24% of the insecticides and 11% of the pesticides used globally, harming both farmers and involved communities, and also requires a large consumption of water and fertilizers.

ORGANIC COTTON

The cultivation of cotton through organic farming protocols allows for the drastic reduction - up to the total elimination - of all harmful chemical substances. With this approach, even small quantities of water are used, the quality of the soil is increased and better working conditions are promoted for people involved in the supply chain.

Furthermore, the promotion of sustainable cultivation practices requires a strong investment in the training of farmers, who can draw on specialist knowledge and trigger virtuous processes of improvement in the management of land and crops, as well as an expansion of the offer.

COTTON MADE IN AFRICA

Cotton that comes from small African producers for whom cultivation contracts represent a guarantee of safe and dignified work. The crops follow a standard that regulates the use of soil and water and preserves biodiversity. Furthermore, thanks to the HIP (Hard Identity Preserved) system, it is guaranteed that the fiber, the thread and the product contain exclusively Cotton Made in Africa.

RECYCLED COTTON

To further reduce the impact of our activities and promote the valorisation of end-of-life materials, at OVS we actively support the choice of recycled materials. We make great use of it in denim, where we are able to improve the impact of our products without compromising their quality. Furthermore, we are developing solutions for the large-scale use of recycled cotton also in knitwear.

BETTER COTTON

Better Cotton is the world's leading sustainability initiative for cotton. Better Cotton Farmers use water efficiently, care for the health of soil and natural habitats, reduce the use of the most harmful chemicals, and respect the rights and well-being of workers. Better Cotton's mission is to help cotton communities thrive while protecting and restoring the environment.

Among other activities, Better Cotton trains cotton farmers around the world on how to grow cotton in their environment and context. Better Cotton is purchased through a chain of custody system called “mass balance.” This means that Better Cotton is not physically traceable to the final products, however, Better Cotton Farmers benefit from the demand for Better Cotton. Mass balance is a volume tracking system that allows Better Cotton to be replaced or mixed with conventional cotton along the supply chain, while simultaneously ensuring that the amount of Better Cotton sold never exceeds the amount of Better Cotton purchased.

Click here to find out more.OVS ITALIAN COTTON

In 2022, 2023 and 2024 OVS invested in the production of organic cotton in Sicily with which two collections of men's and women's t-shirts were produced, entirely traced thanks to the use of a chemical marker applied to the raw material during the ginning phase. Starting from the autumn-winter 2025 collection, the approval of Cotone Italiano comes from Puglia.

The initiative represents an important turning point for OVS, because the management of the production of the raw material allows to control the impacts directly along the entire supply chain.

-

Synthetic fibres

Polyester is the most used synthetic fibre in OVS collections followed by polyamide. The use of recycled synthetic fibres reduces dependence on oil as a source of raw materials and greenhouse gas emissions from production, for this reason OVS is committed to reaching 70% recycled polyester and polyamide by 2026 and to integrating new recycled synthetic materials into the collection, such as recycled acrylic and elastane.

-

Fibers of animal origin

The use of animal origin materials is residual compared to the entire OVS collection. In the few cases in which is used it comes from certified production processes that exclude any suffering to animals and guarantee full control of the entire supply chain.

WOOL

Wool products represent a small percentage of our collections, approximately 1%. Since 2024, we have favored the use of recycled fibers of animal origin with the goal of reaching 50% recycled wool by 2026.

-

Cellulose fibres

From the cellulose extracted from the wood of the trees, are obtained fibers which are used in the clothing sector. Cellulose materials represent 4% of the total fibers used by OVS. It is encouraged the use of those coming from forests managed according to the FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification) standards and suppliers who adopt processes controlled like Lenzing™, which guarantees both the origin of the raw material and low impact production processes.

By 2030, 100% of cellulosic fibers will come from traceable sources or will be chosen from branded materials that guarantee a reduced environmental impact, such as materials from Lenzing™.

PRODUCT CERTIFICATIONS

OVS has been certified OEKO-TEX Standard 100 (Class I and Class II) for more than 25 years. A reference standard with over 21,000 manufacturers, brands and retailers in more than 100 countries, OEKO-TEX® is based on the principles of safety, transparency and trust in the textile sector, supported by verified scientific evidence. The Oeko-Tex Standard 100 guarantees the safety of clothing, from yarn, to fabric, to accessories, up to the finished garment.

PRODUCT CERTIFICATIONS

In 2025 OVS obtained the GOTS, OCS, RCS, GRS certifications which guarantee the content of recycled and organic material in the products and strengthen the traceability strategy of the production chain along the entire value chain and improve transparency in communication towards the customer.

THE SAFETY OF OUR GARMENTS

All our garments are chemically tested to ensure they comply with the limits we have defined for the use of potentially hazardous substances, in accordance with the European regulation 1907/2006 EU (REACH).

Download our Restricted Substance List (RSL) to find out more.

In addition, the most relevant physical performances (e.g. home washing tests) for the quality of the final product are also tested.

PACKAGING

OVS has implemented a comprehensive lifecycle management program for its logistics packaging, allowing it to be reused multiple times in distribution processes after use, creating value and reducing waste. The packaging design is optimized to reduce paper waste during production. At our Pontenure warehouse, we have also implemented a process to reuse wooden transportation pallets. 100% of the polybags used for transport from production countries and the plastic hangers are made from recycled materials. Furthermore, the Pontenure logistics center has implemented a recovery program for boxes and pallets, allowing them to be reused.

USE AND DISPOSAL OF PRODUCTS

In 2024 OVS produced 169,029,843 garments (in 2023 were 196,740,204). Being sustainable requires constant attention not only towards the production phases of the garments, but also towards their use and end-of-life management. We promote various activities to extend the life of products.

| Preconsumer* waste breakdown | 2024 | 2023 |

|---|---|---|

| Unsold | 18,358,743 items | 22,467,850 items |

| Refurbished | 14,378,043 items | 14,488,801 items |

| Stock | 3,920,334 items | 7,951,850 items |

| Charity | 17,802 items | 17,973 items |

| Disposal | 42,564 items | 9,226 items |

*Here preconsumer waste is considered usold garments.

-

Management of refurbished products

Over the years we have perfected a program for the reconditioning and distribution of unsold goods, which allows us to reduce the quantities addressed to the off-price channel or for waste disposal to a minimum. Each year, since 2021, more than 11 million garments were refurbished and redistributed to our sales network.

-

Upcycling

In 2022 we launched REUP, a project of upcycling born from the recovery of unsold, reconditioned and personalized clothes. The garments are customized by young people with intellectual disabilities from Valemour, a social enterprise that promotes the inclusion of fragile people in structured working contexts.

OUR CONTRIBUTION TO THE SUSTAINABLE DEVELOPMENT GOALS (SDG)

EXPLORE THE OTHER SECTIONS